Process

Our Process engineers can help our customers develop a manufacturing process to meet the customers cost budgets, production requirements and component volumes.

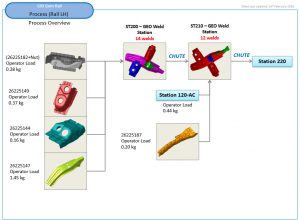

With a vast amount of knowledge and experience from previous projects and the advanced software tools we use, we can quickly offer different scenarios within the factory of how the final product can be built and assembled. This is usually part of the simultaneous engineering phase where the client is designing the component / product and we are working concurrently designing a process. Typical process studies contain the following steps:

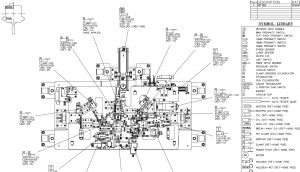

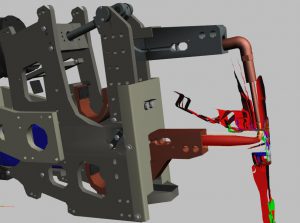

- Fixture Clamping concepts to develop a holding locator strategy for the parts

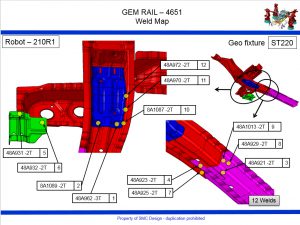

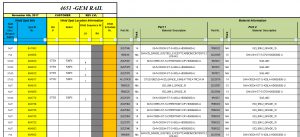

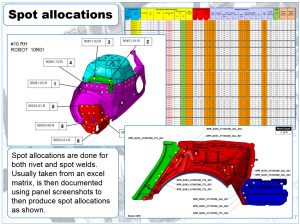

- Joining Study to allocate a quantity of fixings for each robot or operator task

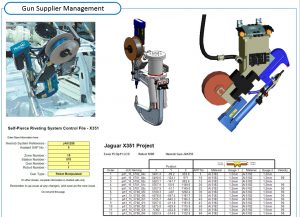

- Gun Study to define a weld gun / Rivet gun type and configuration

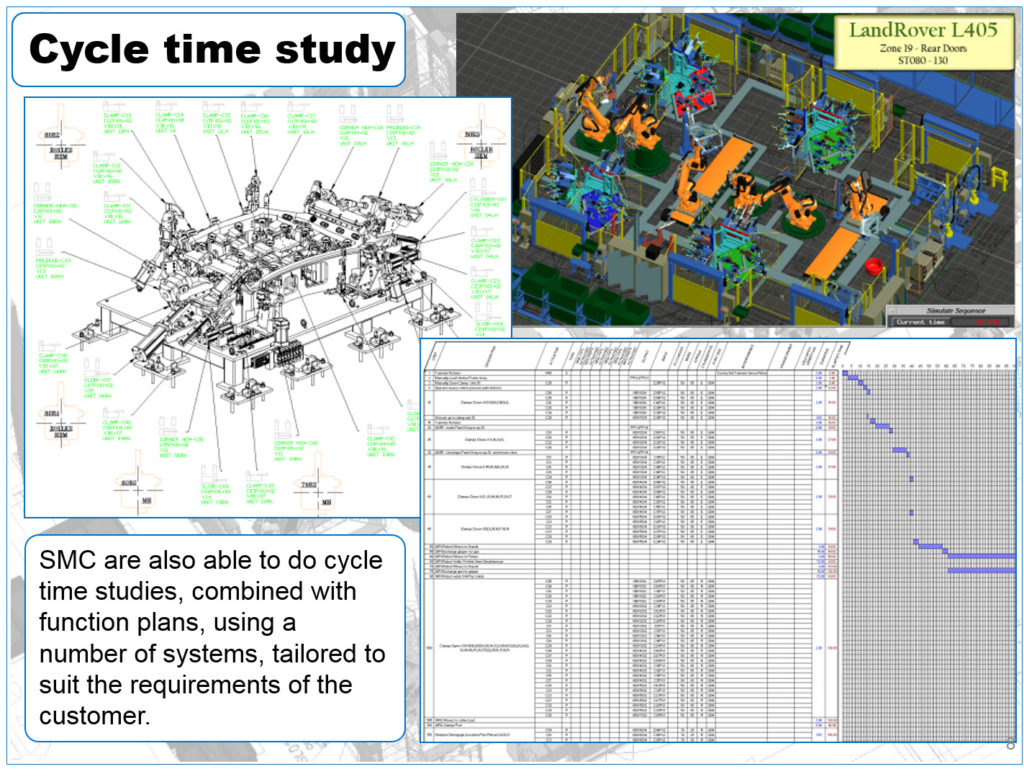

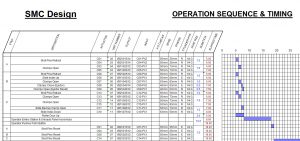

- Cycletime Study to assess the process time will result in a build volume

- Factory Layout to confirm quantity of fixtures, Robots and ancillary tooling required

- Simulation study to prove reach of robots and placement of equipment in the layout

- Ergonoimc study to prove operator interactions